Heavy Loads

Ideal Control

| Download Specs Below |

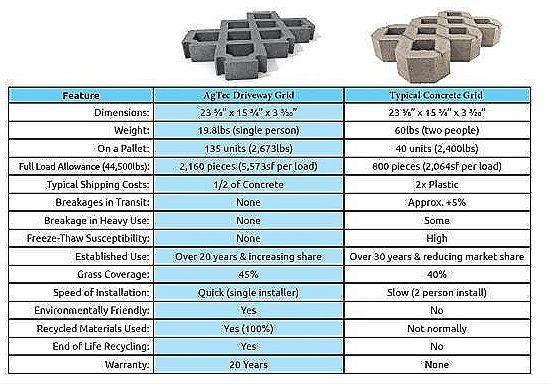

Standard concrete units have a flexural strength of at least 725 psi. HDGG achieves 2,200 psi so it can flex under pressure instead of cracking. Typical trucks exert a static tire load of around 120 psi. The HDGG crushing strength of 2,600 psi means it can bear virtually any load.

HDGG is not plagued by frost damage (unlike concrete), is lightweight by comparison and very robust when handled. HDGG doesn’t crack if dropped, it can be carried/installed by a single person and complies with manual handling guidelines.

FEATURES:

- HDGG is a high-quality porous paving system made from 100% recycled plastic. It’s easy to install and designed for extreme loads like truck parks, rest stops and loading areas.

THE BASICS

- HDGG comes ready to be installed on a level layer of grit over a porous granular base. The tongue and groove makes it easy to create a porous surface that’s strong enough for trucks, buses and forklifts. HDGG can have a gravel or grass finish, in keeping with the surroundings.

Low Impact Development (LID)

- When used as part of a LID, HDGG is an integral part of any sustainable development with a porous base that allows rainwater to drain naturally. LIDs are designed to keep drainage levels similar to those that occurred naturally before development. LIDs help minimize water run-off, reduce flood risk, improve water quality, encourage biodiversity and are an increasing method of urban design.

Unlike wood, concrete or steel, weather isn’t a problem for Heavy Duty Ground Grids. It’s also lighter than concrete and cheaper than steel. Heavy Duty Ground Grids will never rot or rust. It won’t splinter with age or crack in extreme cold. It’s easy to work with, looks good all year round and needs little or no maintenance.

Heavy Duty Ground Grids are completely moisture-repellent and loves wet or damp conditions. It is produced without preservatives, is non-toxic and non-polluting. Best of all, it reduces the strain on landfill and is 100% recyclable.

TRIED & TESTED

- Porous paving is increasingly used in North America and worldwide for access, parking lots, truck parking and bus terminals. The first porous paving systems were made of concrete, but concrete has weight, flexibility and durability limitations. This is why grids made of 100% recycled plastic are so effective.

- As well as environmental benefits and the ability to take very high dynamic loads, HDGG flexes under pressure rather than breaking like equivalent concrete products.

- These high quality heavy duty grass, gravel and paddock paver grids have been specially designed for ground reinforcement and mud control with equine use in mind.

- The HAHN Heavy-Duty Ground Grid with unique interlocking system, is lighter than concrete equivalent grids, making transport and installation much easier.

- Perfect for parking lots, driveways, overflow parking, laneways, fire lanes and much more. Made from 100% recycled plastic, they are highly durable (load capacity of 60 tons!) and resistant to cracking, unlike concrete versions.

- Fill with grass seed or gravel to support effective drainage and reduce environmental impact of the structure.

Interested in finding out more?

Thank you for contacting Grid as New Mud Control Grids.

We will get back to you as soon as possible.

Please try again later.

Contact - Email or Call Today!

Call today!

Call: 1-844-MUD-GRID (1-844-683-4743)

Direct: 1-603-722-8227

In Person - Pick up in Derry, New Hampshire

Delivery & Install Available -

Please or email for more info.

All Rights Reserved | Grid As New, Mud Control Grids

Are you already a customer? Would you mind leaving us a review through the link below. This really helps us reach more people and lets folks know how great these work. Thank you!

Website created by Jennifer Design